- USA 1-888-913-9517

- Canada 1-905-272-2247

N'Take: Environmentally Friendly Factory

You are here: Home \ Factory Information

Our Factory

- The production of N’Take reusable bags is an environmentally-friendly process that generates virtually no waste. There are no smokestacks, chemical residues or other adverse environmental effects in the manufacture of our carry bags. Check out the images below to see our different processes. Our factory incorporates quality checks at every stage, from initial printing, to color reference checks and the final stitched seams.

Polyfabric™ Process

Our most popular durable material is Polyfabric™. The raw material is transferred to a hopper, made into rolls and finally dyed with environmentally friendly inks. There are over 30 stock colors to choose from - or you can get a custom color made for you!

- 1. Raw material to make fabric

- 2. The raw material production

- 3. Material production

- 4. Finished rolls of Polyfabric™

OPP Film Process

- Another commonly chosen material is OPP Film. This material allows full-color CMYK artwork to be used (like a photograph). The process involves printing on OPP Film, which is then adhered to Polyfabric™ material. It is then cut and sewn, much like a standard silk-screened bag, and finally undergoes a stringent quality control check.

- 1. Solid metal rollers used to print the film

- 2. Multi-color printing press

- 3. Lamination and finished roll of material

- 4. Cut material (before sewing) and QC process

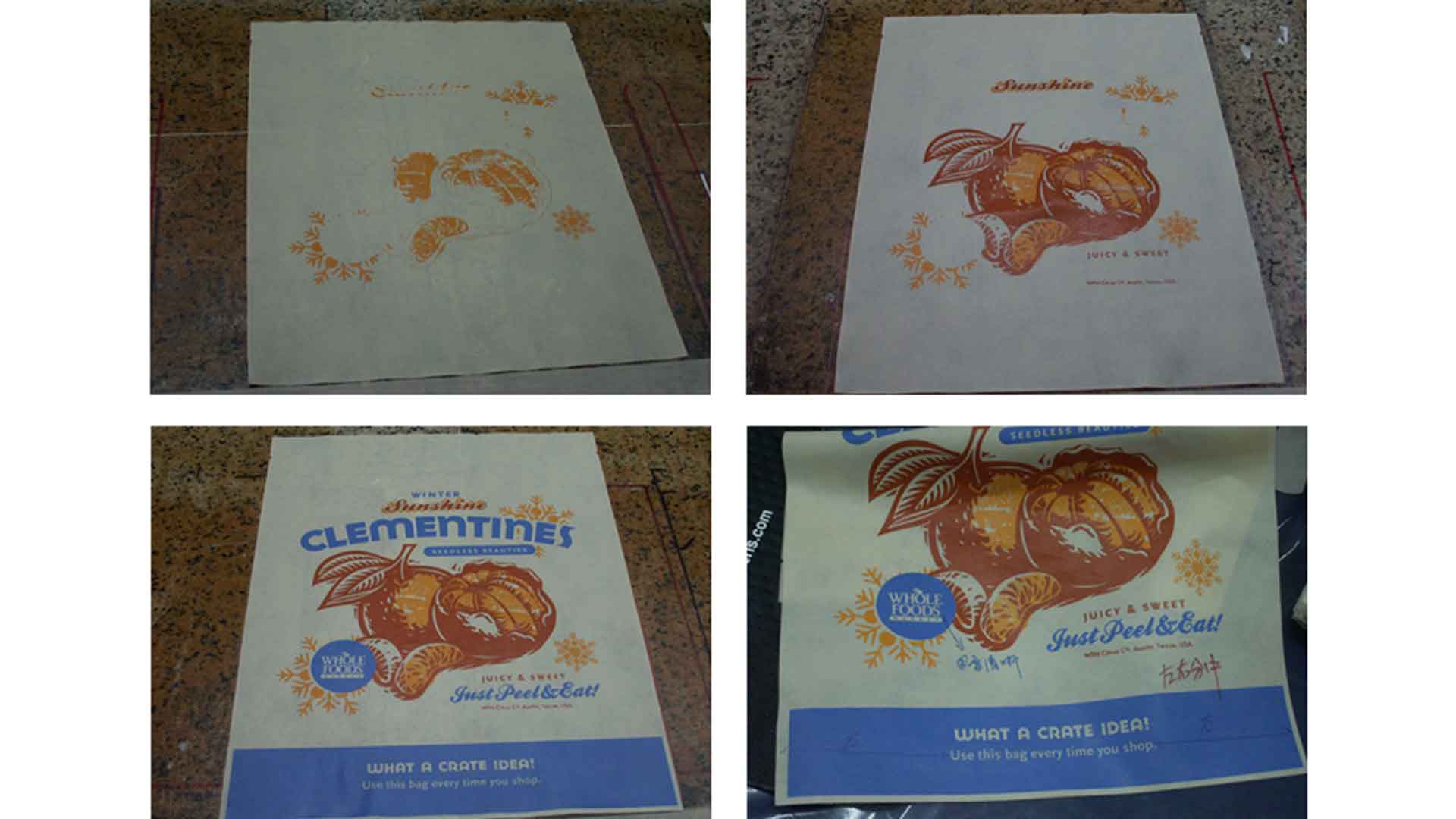

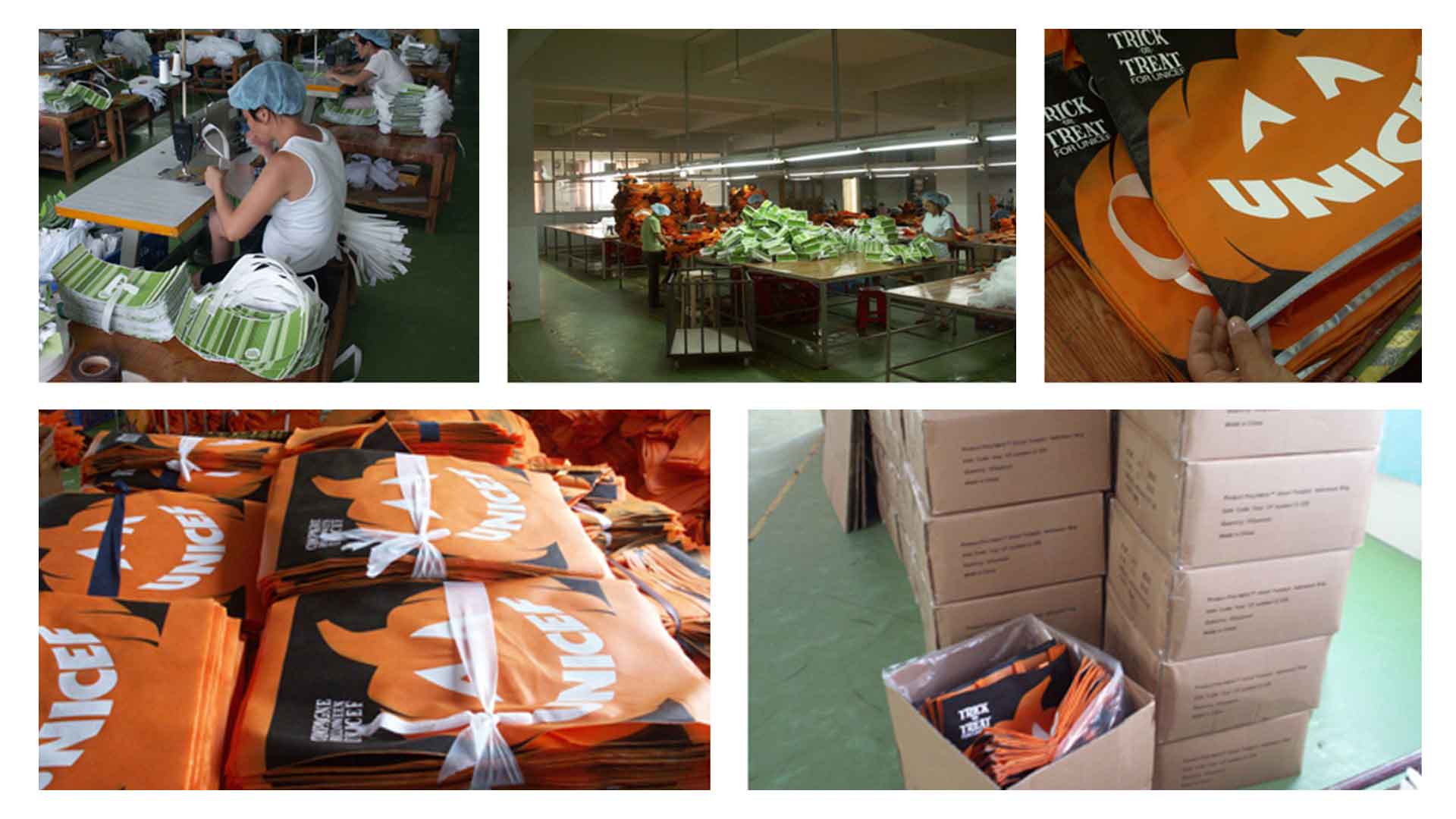

Silk Screen Process

- Silk screen printing is a technique, used in T-shirts as well as bags, where ink is transferred to material through a fine mesh. A rubber blade is drawn across ink laid on the screen, which filters through the open mesh areas on to the Polyfabric™. One color is printed at a time, so this process is repeated, layer-by-layer, until the artwork is complete. After the ink has dried, each panel is hand-inspected and any errors are retouched by hand. Finished panels are then sewn together and the bags undergo more quality control steps until they are finally packaged and ready to ship.

- 1. Silk screen frames and Silk screen tables

- 2. Color is applied, layer by layer

- 3. Quality Control and Hand-retouching of errors

- 4. Sewing, final quality control and packaging